Biosourced Resins

Issued from a past NSERC Industrial Research Chair for Colleges in Renewable Thermoset Resin Development for the Composite Industry, the research theme focuses on the development of new, less toxic thermosetting resins from renewable materials. Studies have led to the consolidation of two areas of expertise: renewable materials and polymers. In earlier projects, Dr. Thibeault’s team demonstrated that epoxy and vinyl ester resins can be made easily from renewable materials.

In fact, a first project on bioplastics led to the development of a renewable styrene-free vinyl ester resin, which could be formulated with over 95% renewable materials through new biotechnology.

In a second oleochemistry project, syntheses were developed and relevant targets were identified for renewable epoxy applications. The consolidation of this expertise has helped establish this Chair program.

As part of this work, a first patent was issued to Kemitek, whose title is “Cardanol Glycidyl Ether Derivatives” (U.S. Patent No 10,035,754).

Great interest for thermoset resins in the composites industry

The polymer materials and composites industries are facing significant challenges, where certain solutions seem difficult to implement or require important innovations. Today, the composites industry still depends on petroleum and keeps a close eye on the short-term price fluctuations of raw materials. Others are preoccupied by growing restrictions, sanitary and environmental, actual or future.

Thermoset resins involve chemistry which has seen little evolution since they first appeared in the mid-20th century. These toxic petrochemical resins, from non-renewable sources and their inherent environmental risks are not readily substituted by greener and safer materials.

A strong impact on organizations following work done by the Research Chair in developing renewable thermosetting resins for the composites industry

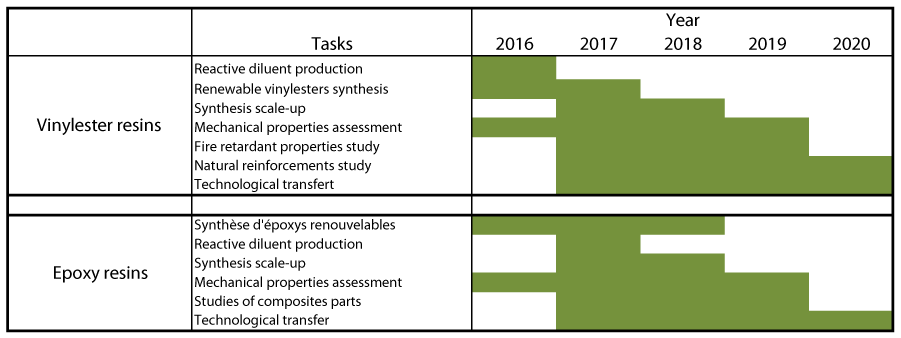

Table: Work Schedule

These new resins have a great impact on many levels, beginning with industrial partners who can aim for new markets in the fields of transportation, energy and sanitary infrastructures. The manufacturers of composites will also be the first to benefit from the research as the developed products will replace traditional resins currently used. Direct and indirect users of composites will also enjoy the health benefits. New markets will be accessible to the industry taking into account the unique characteristics of new products, which will generate new economic activity.

The knowledge acquired in this program will be used today and for future generations and will allow our nation to position itself in the global market for this expanding field. It is forward-thinking to envision the substitutes of the future, before legislative pressure, costs of non-renewable materials and ever-diminishing social acceptability forces the composites industry towards an abrupt change.